Emergency Maintenance

Maintenance Scheduling

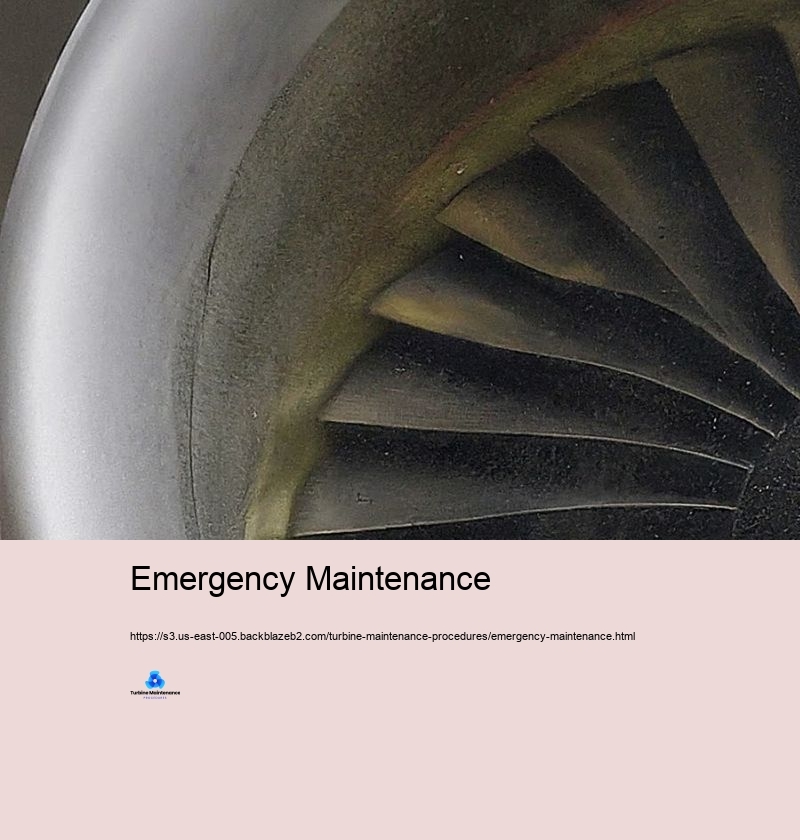

Turbine maintenance is an essential component of power generation, business processes, and many other applications where wind turbines play a crucial function. Appropriate maintenance makes certain optimum performance, prolongs the life span of the tools, and prevents costly malfunctions. This intro to turbine maintenance checks out the crucial ideas and methods crucial for maintaining these complex equipments properly. At its core, turbine maintenance is about maintaining the security and effectiveness of the turbine system. Wind wind turbines, whether heavy steam, gas, or hydraulic, are ingenious pieces of equipment that change power from a fluid (heavy steam, gas, or water) right into mechanical energy. The high-speed turning, extreme temperature level levels, and pressures associated with their treatment make regular and comprehensive maintenance vital. Amongst the necessary concepts in turbine maintenance is preventative maintenance. This favorable approach involves routinely established assessments, cleaning, and little fixings to quit major failures prior to they occur. Preventative maintenance frequently contains tasks such as lubricating bearings, examining and changing clearances, taking a look at blades for wear or damages, and examining resonance levels. By solving little worries early, preventative maintenance can substantially decrease the risk of devastating failings and increase the turbine's operational life. Condition-based maintenance is an added vital concept that has in fact obtained prestige with the growth of sophisticated monitoring modern technologies. This strategy depends on real-time information from sensors and keeping an eye on systems to determine when maintenance is crucial. Parameters such as resonance, temperature level, stress, and oil condition are constantly inspected. When these criteria deviate from typical varieties, it programs potential worries that require interest. Condition-based maintenance licenses much more targeted and reliable maintenance jobs, minimizing unnecessary downtime and enhancing source part. Preparing for maintenance takes condition-based maintenance an activity better by making use of data analytics and machine learning solutions to anticipate when failings are most likely to take place. By assessing historical information and existing operating problems, anticipating maintenance systems can forecast possible worries before they manifest as visible issues. This strategy allows maintenance teams to intend treatments at the most opportune times, lessening disruption to procedures and taking full advantage of the efficiency of maintenance jobs. Positioning is a necessary technique in turbine maintenance. Correct positioning of the turbine shaft with the generator or driven tools is important for smooth procedure and long life. Inequality can produce too much resonance, sped up wear of bearings and seals, and reduced effectiveness. Routine placement checks and changes, typically using laser positioning tools, are a common component of turbine maintenance regimens. Stabilizing is one more crucial aspect of turbine maintenance. The high-speed turning of turbine components methods that even small imbalances can cause considerable resonance and put on. Dynamic balancing of rotors and impellers is performed to guarantee smooth procedure. This process involves including or eliminating small amounts of weight at particular suggest accomplish optimal balance. Typical vibration assessment assists establish discrepancy concerns early, enabling prompt adjustments. Assessment and cleaning of turbine blades are vital maintenance methods. Emergency Maintenance Blades can fight with numerous issues such as disintegration, corrosion, fouling, or physical damages. Routine analyses, often utilizing borescopes or other non-destructive evaluating methods, aid figure out these issues. Cleaning up of blades, which might consist of chemical cleansing or mechanical techniques like grit blasting, aids maintain aerodynamic performance and quits efficiency devastation. Lubrication monitoring is a vital aspect of turbine maintenance. Appropriate lubrication of bearings, equipments, and other relocating parts is essential for decreasing rubbing and put on. This involves not just making certain an enough supply of lube however in addition checking its premium quality. Oil evaluation is a regular method that aids area pollutants, use bits, and adjustments in oil homes that might show creating concerns in the turbine system. Seal maintenance is an additional vital approach. Seals secure against leakage of operating liquids and lubes, and their falling short can cause substantial performance losses and possible protection threats. Routine assessment and substitute of seals, specifically in high-pressure or high-temperature locations, is a fundamental element of turbine maintenance routines. Control system maintenance is considerably essential as wind generators end up being much more automated and electronically managed. This consists of routine checks and calibration of picking up units, actuators, and control valves. Software updates and cybersecurity actions are likewise essential components of modern turbine control system maintenance. Security is vital in all turbine maintenance tasks. Turbines involve high powers, extreme temperatures, and possibly unsafe materials. Extensive adherence to security methods, consisting of lockout/tagout procedures, constrained area entrance procedures, and appropriate use of individual security devices (PPE), is vital. Security and security training and normal document program for maintenance employees are crucial techniques in turbine maintenance programs. Records and record-keeping are important techniques in turbine maintenance. Comprehensive logs of all maintenance tasks, including evaluations, repair service solutions, and part substitutes, supply beneficial historic info for pattern examination and future maintenance preparing. Several organizations currently use electronic maintenance administration systems (CMMS) to simplify this process and promote information evaluation. Training and capacity development of maintenance employees is a recurring method in turbine maintenance. As turbine modern technologies breakthrough, maintenance approaches and tools likewise development. Regular training programs make sure that maintenance team are updated with the most current maintenance techniques, analysis gadgets, and security and security procedures. Ecological considerations are happening increasingly crucial in turbine maintenance. This consists of proper handling and disposal of harmful products like made use of oils and cleansing chemicals. Numerous maintenance techniques now focus on reducing ecological influence while making certain ideal turbine efficiency. Turbine maintenance is a complex and diverse field that combines mechanical, electric, and substantially, electronic capability. The essential concepts of precautionary, condition-based, and predictive maintenance type the foundation of contemporary turbine maintenance methods. Practices such as positioning, balancing, blade evaluation and cleansing, lubrication keeping an eye on, and control system maintenance are essential for guaranteeing the stability, efficiency, and long life of turbine systems. As turbine contemporary innovations remain to establish, maintenance methods will in addition breakthrough, consisting of new innovations and methods to fulfill the problems of maintaining these vital tools in an ever-changing power landscape.